FOREMOST SIGNS

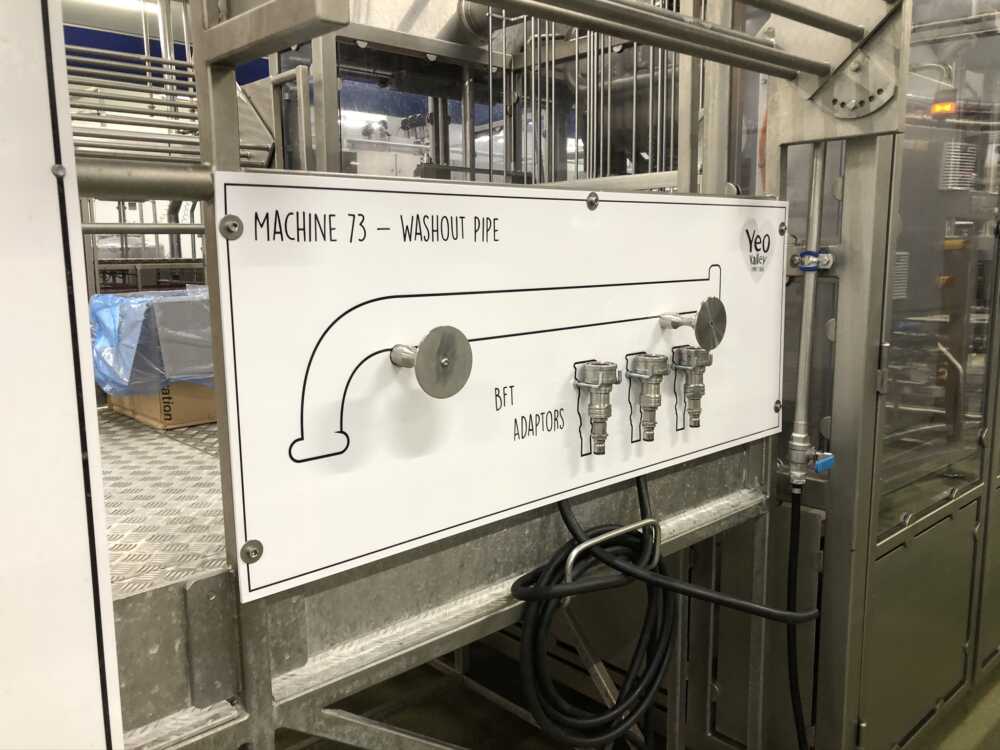

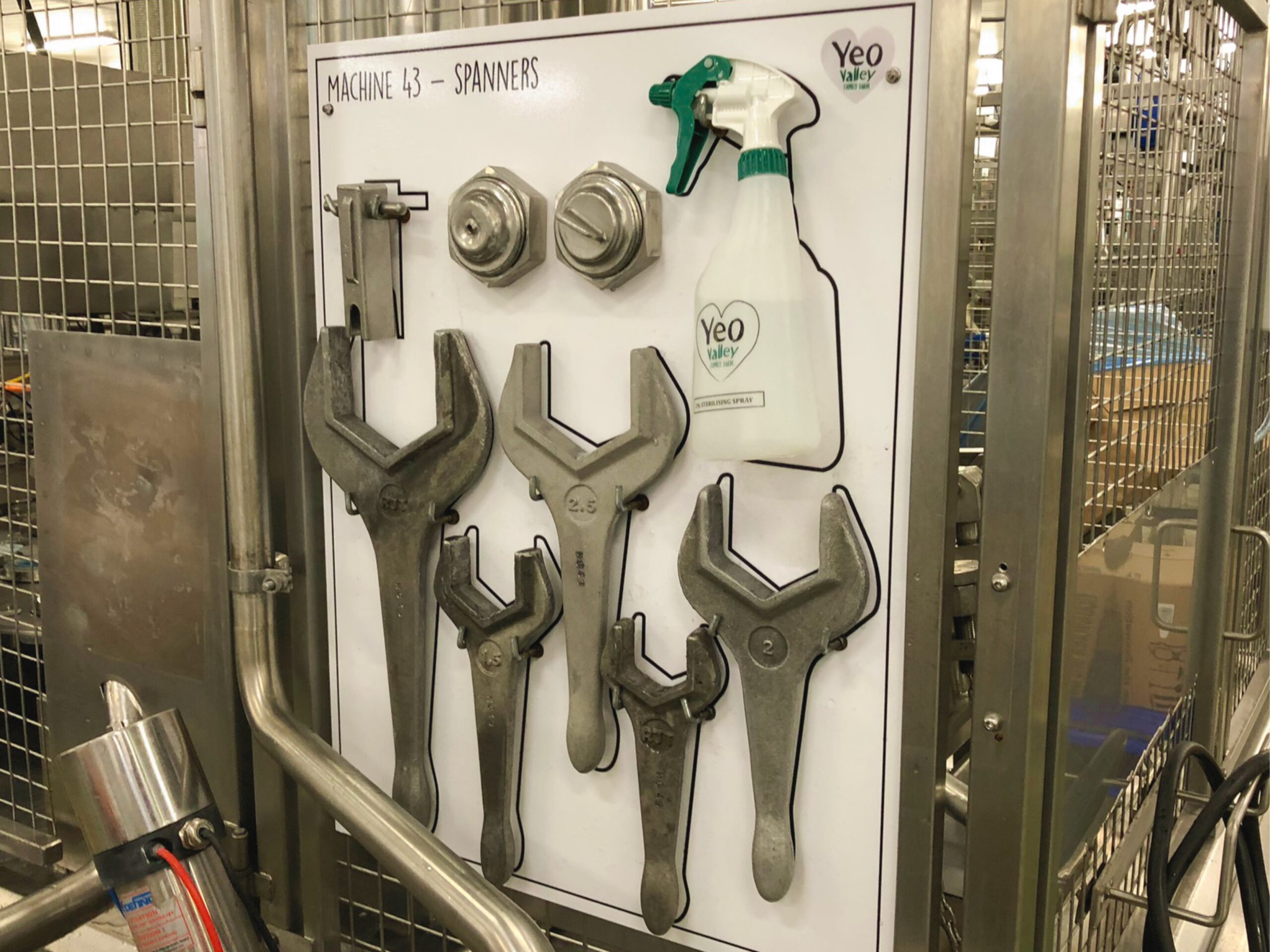

SHADOW BOARDS

Visualise, Organise, Optimise

Shadow Boards bring the 6S Principles to life by giving each tool and piece of equipment its own spot.

What is 6S Lean:

5S + Safety

6S, also known as 5S + Safety, is a methodology designed to enhance productivity and maintain a safe work environment. Building upon the core 5S principles—Sort, Set in Order, Shine, Standardise, and Sustain—the 6S approach incorporates Safety as an essential component. This system not only fosters efficiency within the workplace but also reinforces a long-term culture of safety and organisation.

We know that Safety is the topmost priority in every workplace. Having a safe and clean working environment helps:

- Create a positive impact on productivity and quality;

- encourage a stress-free and healthy atmosphere where workers can feel safe and secure; and

- make it easy to recognise potential hazards and install safety controls.

How to place an order for a Shadow Board?

There are several ways we can develop the design for your Shadow Board:

– Send Your Tools to Foremost Signs – If you can temporarily part with your tools or are purchasing new ones, you can send them directly to us. This allows us to ensure each tool fits perfectly on the Shadow Board before shipping it to you.

– Provide Photos and Measurements – If you have a small and straightforward selection of hand tools, you can send us the necessary photo information. This method works well for simpler setups.

– Request an On-Site Visit – A Foremost Signs representative can visit your facility to assess your tooling and gather all the details needed for an accurate design. Depending on your location and the time required, there may be an additional charge for this service.

Cleaning Stations

We utilise a range of high-quality materials for our Shadow Boards, carefully selecting the most suitable option based on the specific application.

The majority of our boards feature a durable laminated vinyl print applied to 10mm rigid plastic, Foamex. This material is both strong and easy to handle, making installation on existing wall spaces straightforward for maintenance teams. For heavier equipment, such as large pipework, we use 2mm aluminium sheets, offering a robust and heavy-duty foundation. Additionally, Acrylic serves as a cost-effective, durable, and aesthetically appealing alternative that creates a high gloss finsh to the face.

To protect the board’s surface, all prints are finished with a laminate protection film, preventing scratches and ensuring long-term durability. Our prints are also wrapped around the edges of the entire board to keep any loose articles trapped inside the vinyl wrap to prevent contamination within food industry areas.

For securing tools onto the board, we use a combination of fixings:

– Stainless steel hooks with countersunk socket screws, washers, and nylon nuts for secure placement.

– Threaded Bolts for heavier tools, providing excellent strength and stability for those larger tools.

Our Different Types of

Shadow Boards

Shadow boards are used for effectivly organising and storing tools and handheld equipment. Whilst they have been recently used for standard tools such as spanners, screwdrivers, and hammers, we also specialise in creating custom shadow boards tailored for other equipment, including machine components, change over parts, cleaning equipment and much more.

By providing a specific location for each tool instead of letting them remain un-organised on the side of the production area, each item has its own specific space for each machine or area that reduces change over times and keeps staff working effectilvly. If an item is missing it allows managers to quickly identify missing or broken items so they can be re ordered quickly.

This method is in harmony with 6S and Lean principles, embodying the idea that there is “a place for everything, and everything in its place.” Each tool is allocated to its designated spot with matching shadows and fixings, enhancing efficiency and organization in the workspace.

Tool Shadow Boards

A organisational system designed to store tools and handheld equipment in a structured, visible, and easily accessible manner. It features custom-cut tool outlines (or “shadows”) that indicate where each item belongs, making it easy to identify missing tools at a glance.

Cleaning Stations

Cleaning Stations offer an effective solution for organising workplace cleaning equipment and tools, ensuring a tidy and efficient environment. The diverse range of cleaning stations available enables you to seamlessly incorporate fundamental 6S principles into your workspace.

First Aid Boards

Elevate your workplace safety and efficiency with our expertly crafted first aid boards. We understand that quick access to first aid equipment is crucial in emergencies. Our boards are designed to showcase a clear, branded layout that not only identifies first aid points but also enhances the visibility of essential supplies.

6S Lean: The 6 Components

and Their Importance

6S (otherwise known as 5S + Safety) is a system that aims to promote and sustain a high level of productivity and safety throughout a workspace. While adhering to the 5S principle of Sort, Set in order, Shine, Standardize, and Sustain, the 6S method adds the concept of Safety. 6 S lean not only helps organizations promote efficient working environments but also establishes a sustainable culture of safety.

1) – Sort (Seiri)

Sorting, the first step in the 6s methodology, aims to reduce clutter and make it easier for essential work items to be easily located for improved efficiency. “Red tagging” is often done to mark unnecessary items for immediate disposal, while “yellow tagging” can be applied for those items that can be temporarily kept off-site for future use.

2) – Set in order (Seiton)

In this stage of the 6 S system, items, equipment, and work materials tagged as essential in the first stage should be placed in an organizsd manner in the most logical locations. The objective of ‘Set in Order’ (or ‘Straighten’) is to establish a systematic way of storing and retrieving items, thus helping maximize accessibility and space.

3) – Shine (Seiso)

After non-essential items have been removed and essential items have been organised, the next step is cleansing. The third stage of the 6s lean system, also known as ‘Shine’, includes activities, such as cleaning the workplace, maintaining its pleasant appearance, and using preventive steps to keep workspaces tidy and clean. The objective is to create an environment that prevents injuries and products from being stained due to uncleanliness.

4) – Standardise (Seiketsu)

‘Standardise’ is the fourth 6s method stage that aims to establish a new workplace norm by identifying best practices and creating consistent procedures for the first three stages. It aims to help people have the same work routines in their processes and develop more efficient habits. This can be done by providing visual reminders, setting expectations of workers’ responsibility, and conducting routine inspections and regular site checks.

5) – Sustain (Shitsuke)

This is the most challenging step of the 6S method as the goal is to ensure that standardized procedures are applied continually over a long period of time until it becomes second nature in day-to-day work.

6) – Safety

Lastly, 6S lean features Safety as the final step added to the standard 5S methodology many have been used to. This essential step of 6 S focuses on identifying hazards and setting preventive controls to keep workers safe during work operations and ensure that the work environment meets required safety standards.

Source: https://safetyculture.com

Contact Options

Opening Times:

Monday – Friday: 8:30 – 17:00

Weekends: CLOSED

Unit 12 Chancellors Pound, Redhill, Bristol, BS40 5TZ

01934 863753

info@foremostsigns.co.uk